Applications

Specification

- Suitable for all type of Industrial liquid handling

- Can Handle Furnace Oil up to 150 Deg. C

- Can work in hazardous area

- Self Powered / Standard Display with Backlight

- Suitable for upto 150 micron impurity liquid

- Accuracy will be within ±0.5 % of total reading

- Suitable for any viscous oil

- Enclosure - Flameproof to IS2148 1981 Certified by CMRS Dhanbad / Non Flameproof - IP 65

Specification

- Suitable for Cummins PT Fuel System

- Accuracy - ± 0.5% of total reading

- Operating Temperature - 0-70 Deg. C

- Display - 8 Digit dot matrix LCD with 6 digit Totaliser

- Inbuilt filter with reusable SS filter Cartridges

- Power Supply - 12 V DC from Cranking Battery

- Mounting - MS fabricated frame

- Enclosure - Flameproof to IS2148 1981 Certified by CMRS Dhanbad

- Flow Range 60-1500 LPH

- Wireless data output with cloud services available

- RS485/Modbus Serial Output available

- Net Totaliser displayed

- Measures the difference between Inlet and Return Lines

Application product not available.

Specification

- Dispensing accuracy at ±0.5% of reading

- RFID tag filling

- Barcode scanning based filling

- Zero chance of pilferage

- Vehicle liquid dispensing

- Petrol Dispensing

- High flow diesel dispensing

Specification

- To fill liquid directly into vehicle assembly

- Complete automated system to achieve daily filling target

- Variable liquid quantity can be easily fill

- Programmable multiple batches to suit a variety of vehicle models

- Accuracy guaranteed to ±0.01 ltr. per batch filling

- Cp/Cpk 1.68 for filling of all types of liquids

Specification

- ±0.1% repeatability

- ±0.5% accuracy

- Kerosene and solvent unloading

- Petrol Unloading

- Diesel unloading

- Above ground and underground tank unloading

- Cloud Services Output

- Pump option available for above-ground tank unloading

- Wireless data transmission

- 100% air-free measurements

- Loading and Unloading any type of liquid from Tanker

- Cross checking against the dip-rod measurement standard

- Accuracy will be within ±0.5 % of total reading

- Suitable for all types of Solvents and chemicals

- Used to measure liquid W/o air count

- Can use in hazardous area with Flameproof Enclosure

Specification

- For Brake / Clutch / PS Oil and Coolant Mix filling Applications

- Main Cycles - Evacuation/ Filling/Suckback/Gun Purge

- High evacuation upto 0.5 mbar suitable for braking system

- Leak check during evacuation cycle for vacuum

- 100% air-bubble free liquid filling

- Leak check during filling cycle for positive pressure

- Liquid suck-back to maintain oil level in reservoir

- Self test for main vacuum pump efficiency

- Diagnostic alarm for easy maintenance and system fault finding

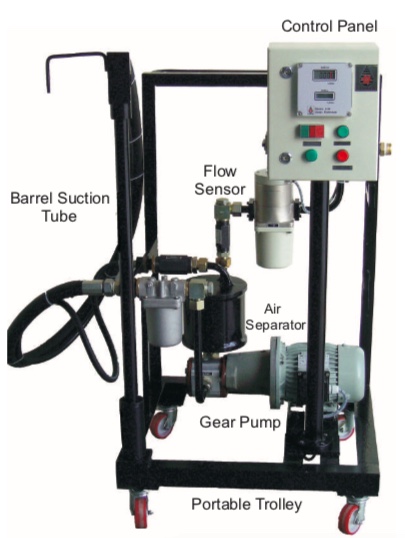

Specification

- Used to empty barrels into storage tanks

- Used to fill liquid directly into vehicle assembly also

- Liquid measured during barrel unloading

- Suitable for all type of liquid, Chemicals, Solvents and Lube Oils

- Measured liquid is always air free

- Accuracy will be within ±0.5% of total reading

Specification

- Accuracy at ±0.5% of reading

- Two-stage valve based filling

- Diesel batching

- Accurate batching of liquids

Specification

- Conversion of Fresh Oil/Used Oil to NAS 8/7/6 Grade

- Dirty Oil cleaning through 4 different types of filters

- Liquid re-circulation pump inside the system

- Used to clean Engine / Transmission Oil / Hydraulic Oil

- Sampling Vales are available for performance testing at each station

- On line checking and display of water PPM content

- Able to handle large amount of liquid at a time

- System can fulfill International standard demand NAS 7/ ISO 18/16/13 grade

Specification

- System can dozing liquid from 1 ml volume

- Used in Paint and Pharmaceutical industries

- System can handle hazardous chemicals and solvents

- 2 or more liquid ratios can mixed at a time

Specification

- Accuracy at ±5% of full scale

- Pump control available

- Above ground level monitoring

- Underground tank level monitoring on BMS

Application product not available.

Specification

- Accuracy at ±0.5% of reading

- For 1500-3000 HP Cummins high HP engines

- 100% deaeration via air separator

- Separate flowmeters for net consumption measurement

Application product not available.

Specification

- Accuracy at ±1% of reading

- Wireless data transmission to Cloud Services

- Data on RS485/Modbus

- 1-30 LPH Measurement flow range

- Accuracy at ±0.5% of reading

- Mining Machinery consumption monitoring

- Construction machinery consumption monitoring

- Small Genset Consumption monitoring

Specification

- Accuracy at ±0.5% of reading

- USed to Cummins Make 500 to 1250 KVA rating engines

- 100% fuel deaeration ensured

- Cummins PT Fuel System compliant

- Engine consumption of compressors, generators

- Air-free consumption calculation

- Net consumption using single flowmeter